AX-Lightness

22. Aug ’13

General

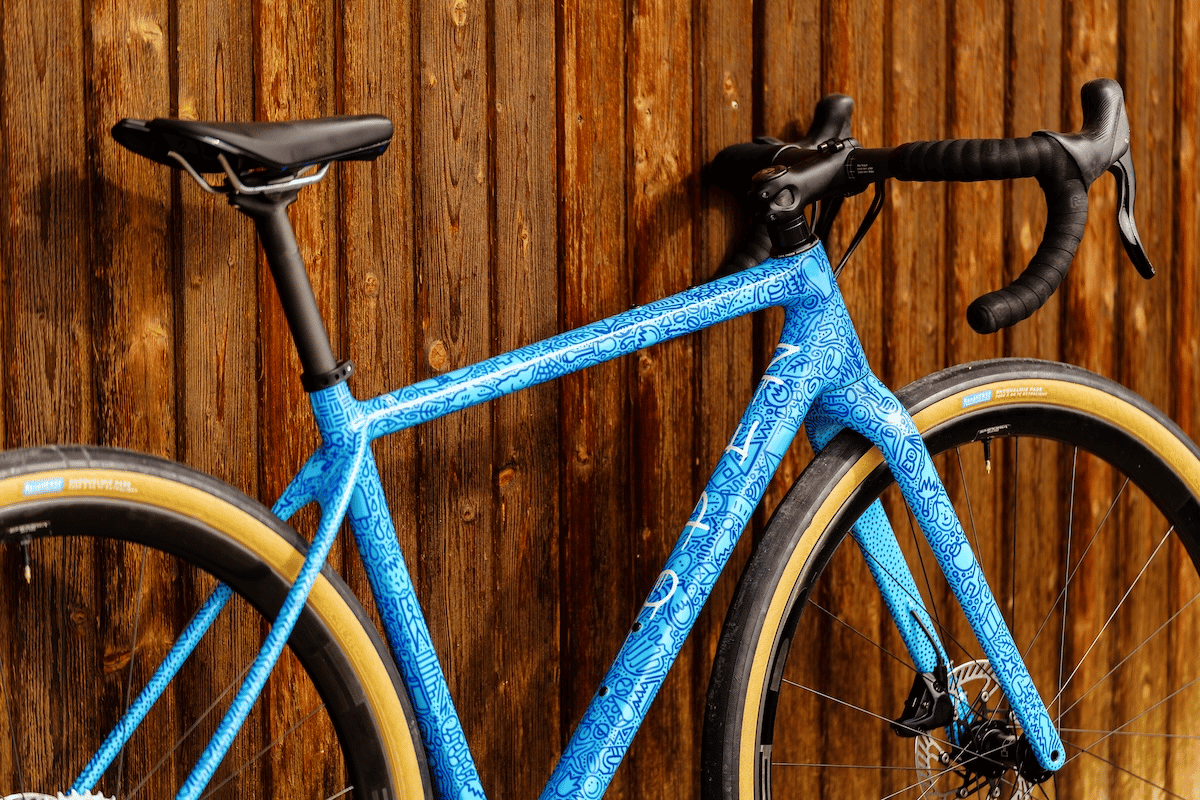

The nice thing about running OPEN is that without the pressure of maximizing sales, we can waste some of our time doing things just because we like them. The Limited Edition models is one such area, when we just try to incorporate parts we really like into our specs. We did that with the AXX1 limited edition and we are readying some new builds for this year's Eurobike. You will be able to see these new builds on the AX-Lightness booth (Hall A2, booth 207).

Since collaborating with AX on the above-shown AXX1, we've started to work with them a bit more closely. They're in the south-east of the former West Germany, in Creussen, not an easy place to get to. In fact it is closer to Prague than to Berlin or Munich. But taking the trouble to get there is worth it.

AX has been growing steadily by building parts for two distinct groups of customers: motorsports and bikes. Walk through their building and you trip over old brake cowlings, mirrors, gullwing doors and driver helmets. AX has produced parts for many LeMans and F1 winning cars. While that's all exciting and fun, it is clear from talking to owner Axel Schurna that his biggest passion is bikes.

Ironically, Axel maintains that the technology for bike parts is often more cutting edge than for motorsports. Most F1 cars are too light anyway, so weight is not a primary concern for a lot of parts. Production speed on the other hand is paramount, as race teams usually work in 1-2 week sprints, the time between races. So if they need something new, they want it fast, not 10% lighter.

On the other hand, some of the shapes they need are very elaborate, with internal channels and all sorts of crazy stuff that you need slides and lost-wax processes for. And because shapes influence aerodynamics and aerodynamics are everything in racing, stiffness is important (you can imagine how much a wing would bend under drag forces when going 300kmh if you don't design enough stiffness into it).

Another great example of this need for stiffness is in a very small part AX makes, the rear view mirrors. If these are not ultra-ultra stiff, they will vibrate and the driver won't be able to see anything in them. So they are made as solid ultra-high modulus pieces (and when they say ultra-high modulus, they mean it, not the bike industry marketing buzz version).

No photos of the automotive stuff, IP has to be protected.

We were allowed to take photos in the bike area, and AX's accomplishments are equally high there. They started with a saddle, an area in which they still rule the weight-weenie-world. My personal favorite is the Phoenix - although not the lightest or maybe "the best", I just love how the deck morphs into a leaf spring and then the rails.

However, their most popular saddles use more standard rails. The rails itself are quite tricky to make, as they need to be very tough to withstand the clamping forces and the impacts whenever you hit a pothole. It's one of the rare parts that is still made through wet lay-up as the extra resin content actually helps the toughness. The saddle decks are made using prepreg. Here you see the untrimmed decks as they come out of the mold.

AX then extended into seatposts, bars, stems, cranks, forks, brakes and wheels, each time making (one of) the lightest products available in each category.

The rim process is actually very interesting, with pins to create the spoke holes rather than drilling the holes afterwards. This method ensures no fibers are cut for the best possible strength and durability.

They even make a few frames, which of course with my background is always interesting to see. It's funny to hear Axel talk about how he would always look forward to Cervélo bringing out a new frame and ask himself "how on earth did they do THAT", pretty much the same way I would always sneak by the AX booth every Eurobike. Of course, back in those days, we never told each other!

Unlike many places, Axel had no problem with me taking photos and sharing them with you. When your processes are so good and you keep innovating, you're not worried about other companies catching up and you love showing off your capabilities. For example, AX has two very nice clean rooms. They are a requirement for automotive, not really that necessary for bike production (good luck finding one, regardless of what people claim). But since Axel has them, many bike parts are made in there too.

The final plus about AX is that they are in Franken, a region of Bavaria not known for light food or lousy beer. So if you're lucky enough to be in the area, visit the Brauerei Kürzdörfer. It is a huge log cabin made of huge logs that houses a brewery, restaurant and guest rooms. The Schnitzel is enormous, the potato salad wonderful and the beer ... I wouldn't know.

Since collaborating with AX on the above-shown AXX1, we've started to work with them a bit more closely. They're in the south-east of the former West Germany, in Creussen, not an easy place to get to. In fact it is closer to Prague than to Berlin or Munich. But taking the trouble to get there is worth it.

AX has been growing steadily by building parts for two distinct groups of customers: motorsports and bikes. Walk through their building and you trip over old brake cowlings, mirrors, gullwing doors and driver helmets. AX has produced parts for many LeMans and F1 winning cars. While that's all exciting and fun, it is clear from talking to owner Axel Schurna that his biggest passion is bikes.

Ironically, Axel maintains that the technology for bike parts is often more cutting edge than for motorsports. Most F1 cars are too light anyway, so weight is not a primary concern for a lot of parts. Production speed on the other hand is paramount, as race teams usually work in 1-2 week sprints, the time between races. So if they need something new, they want it fast, not 10% lighter.

On the other hand, some of the shapes they need are very elaborate, with internal channels and all sorts of crazy stuff that you need slides and lost-wax processes for. And because shapes influence aerodynamics and aerodynamics are everything in racing, stiffness is important (you can imagine how much a wing would bend under drag forces when going 300kmh if you don't design enough stiffness into it).

Another great example of this need for stiffness is in a very small part AX makes, the rear view mirrors. If these are not ultra-ultra stiff, they will vibrate and the driver won't be able to see anything in them. So they are made as solid ultra-high modulus pieces (and when they say ultra-high modulus, they mean it, not the bike industry marketing buzz version).

No photos of the automotive stuff, IP has to be protected.

We were allowed to take photos in the bike area, and AX's accomplishments are equally high there. They started with a saddle, an area in which they still rule the weight-weenie-world. My personal favorite is the Phoenix - although not the lightest or maybe "the best", I just love how the deck morphs into a leaf spring and then the rails.

However, their most popular saddles use more standard rails. The rails itself are quite tricky to make, as they need to be very tough to withstand the clamping forces and the impacts whenever you hit a pothole. It's one of the rare parts that is still made through wet lay-up as the extra resin content actually helps the toughness. The saddle decks are made using prepreg. Here you see the untrimmed decks as they come out of the mold.

AX then extended into seatposts, bars, stems, cranks, forks, brakes and wheels, each time making (one of) the lightest products available in each category.

The rim process is actually very interesting, with pins to create the spoke holes rather than drilling the holes afterwards. This method ensures no fibers are cut for the best possible strength and durability.

They even make a few frames, which of course with my background is always interesting to see. It's funny to hear Axel talk about how he would always look forward to Cervélo bringing out a new frame and ask himself "how on earth did they do THAT", pretty much the same way I would always sneak by the AX booth every Eurobike. Of course, back in those days, we never told each other!

Unlike many places, Axel had no problem with me taking photos and sharing them with you. When your processes are so good and you keep innovating, you're not worried about other companies catching up and you love showing off your capabilities. For example, AX has two very nice clean rooms. They are a requirement for automotive, not really that necessary for bike production (good luck finding one, regardless of what people claim). But since Axel has them, many bike parts are made in there too.

The final plus about AX is that they are in Franken, a region of Bavaria not known for light food or lousy beer. So if you're lucky enough to be in the area, visit the Brauerei Kürzdörfer. It is a huge log cabin made of huge logs that houses a brewery, restaurant and guest rooms. The Schnitzel is enormous, the potato salad wonderful and the beer ... I wouldn't know.